Inside our weaving mill there’s a machine that isn’t constantly in operation, unlike our looms. But the function it performs is a fundamental one: it’s the warper.

What’s the use of a warper?

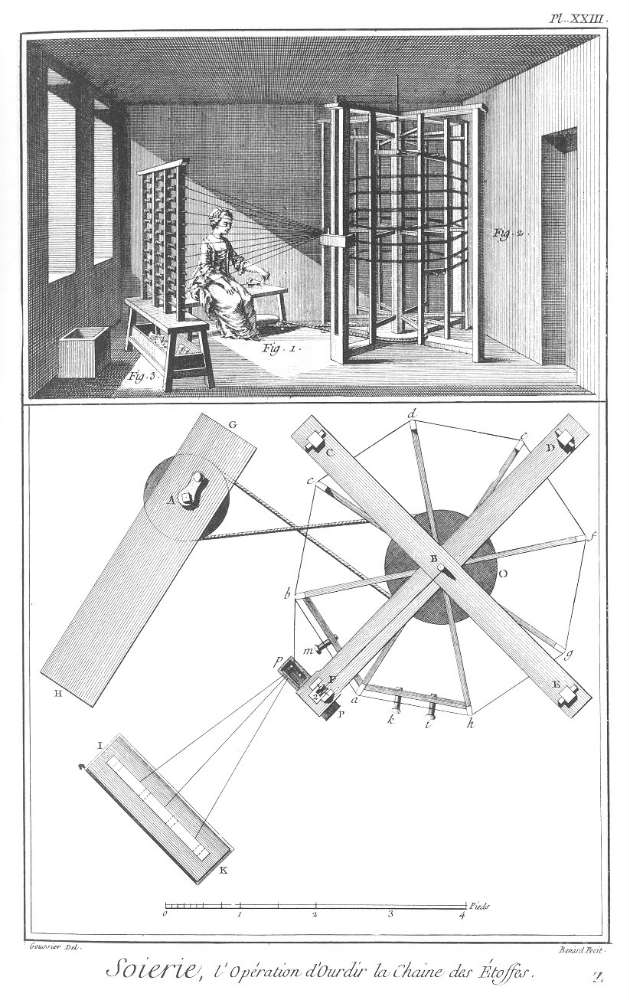

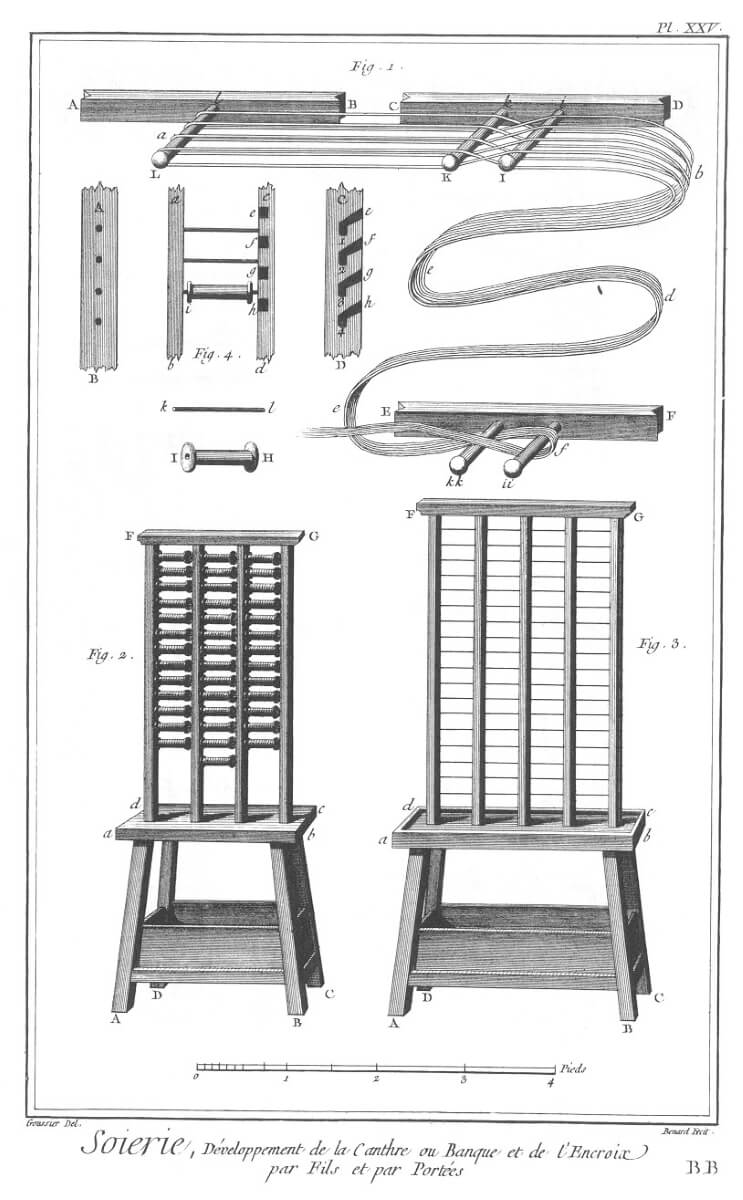

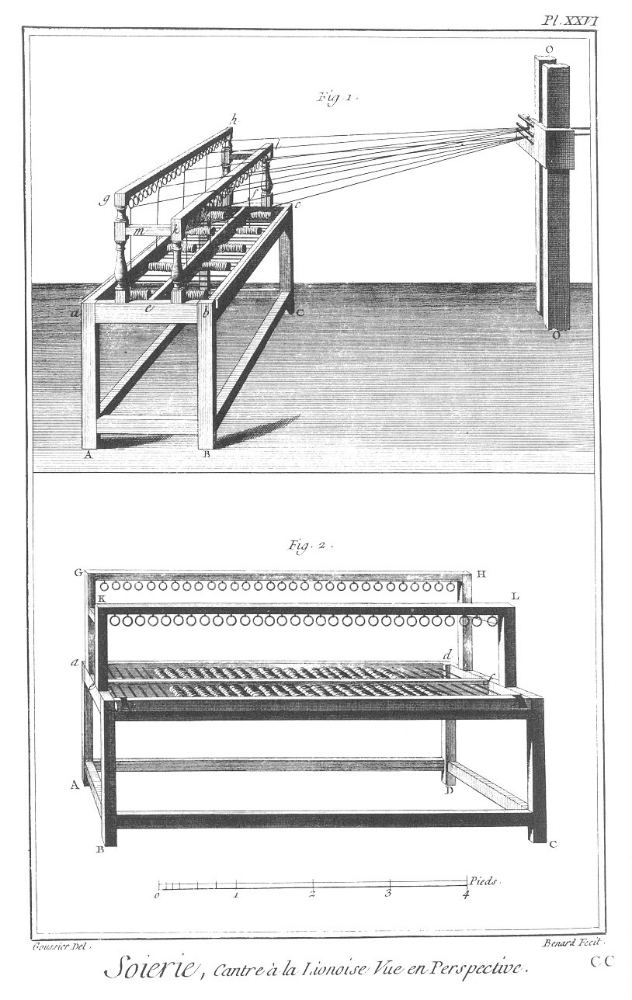

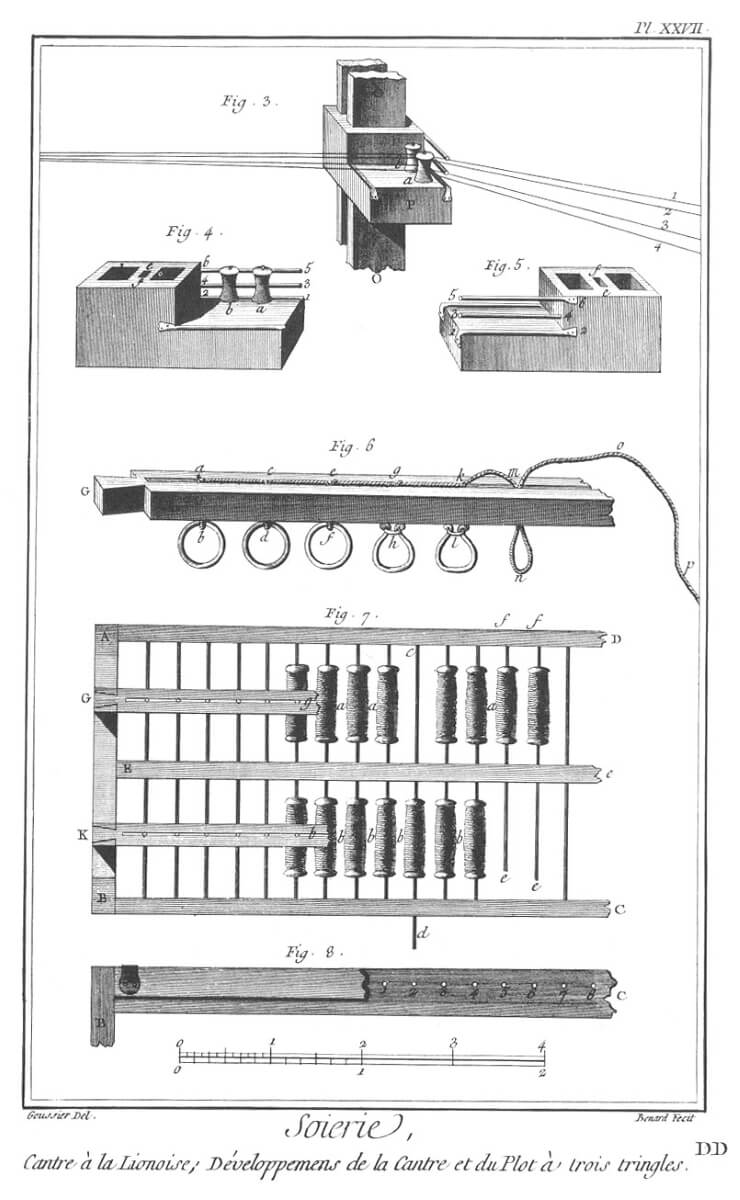

The warper is the machine that prepares the warp, so that it can be used on the loom, through the operation called “warping”. This process consists in placing reels – made of cotton or silk threads – in a creel, the small machine placed next to our vertical warper.

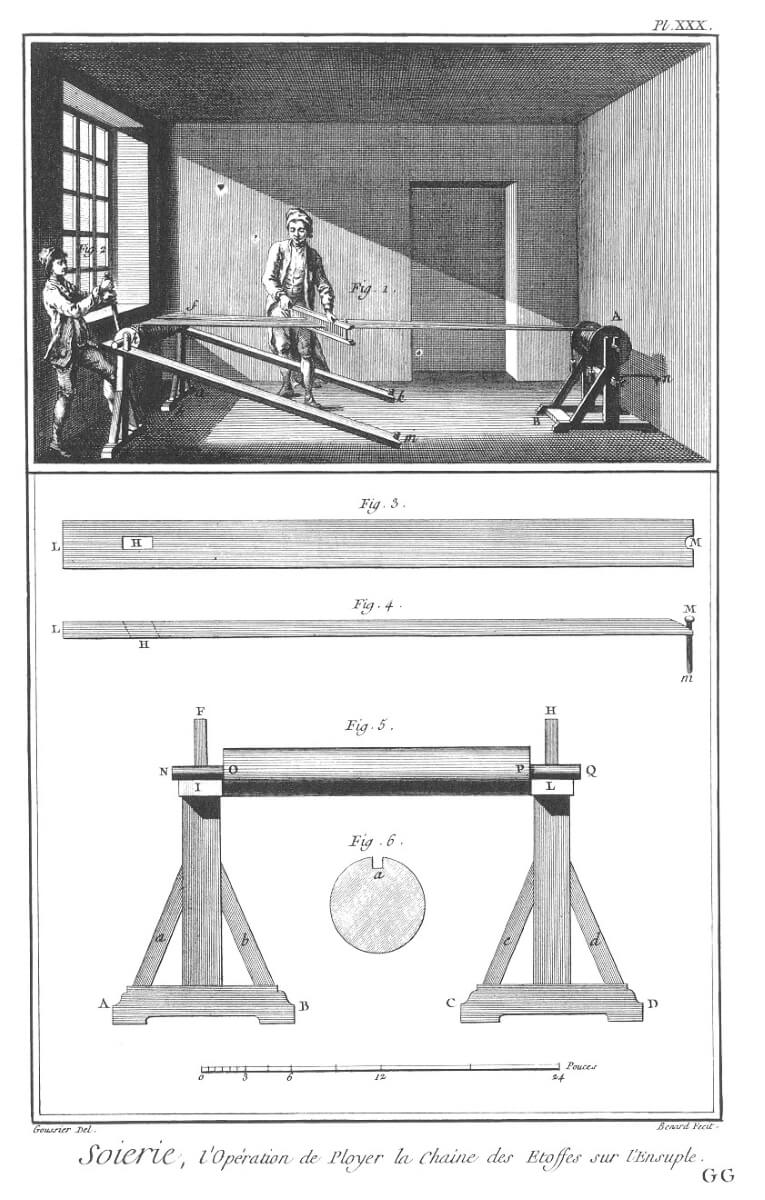

The weaver, operating the warper with a crank, wraps the threads on it. When the threads overlap, they create a single band, and each overlapping separates even and odd threads and creates a cross. This form is necessary to allow the weaver to find the correct position of the threads once the warp is positioned on the loom.

Warping

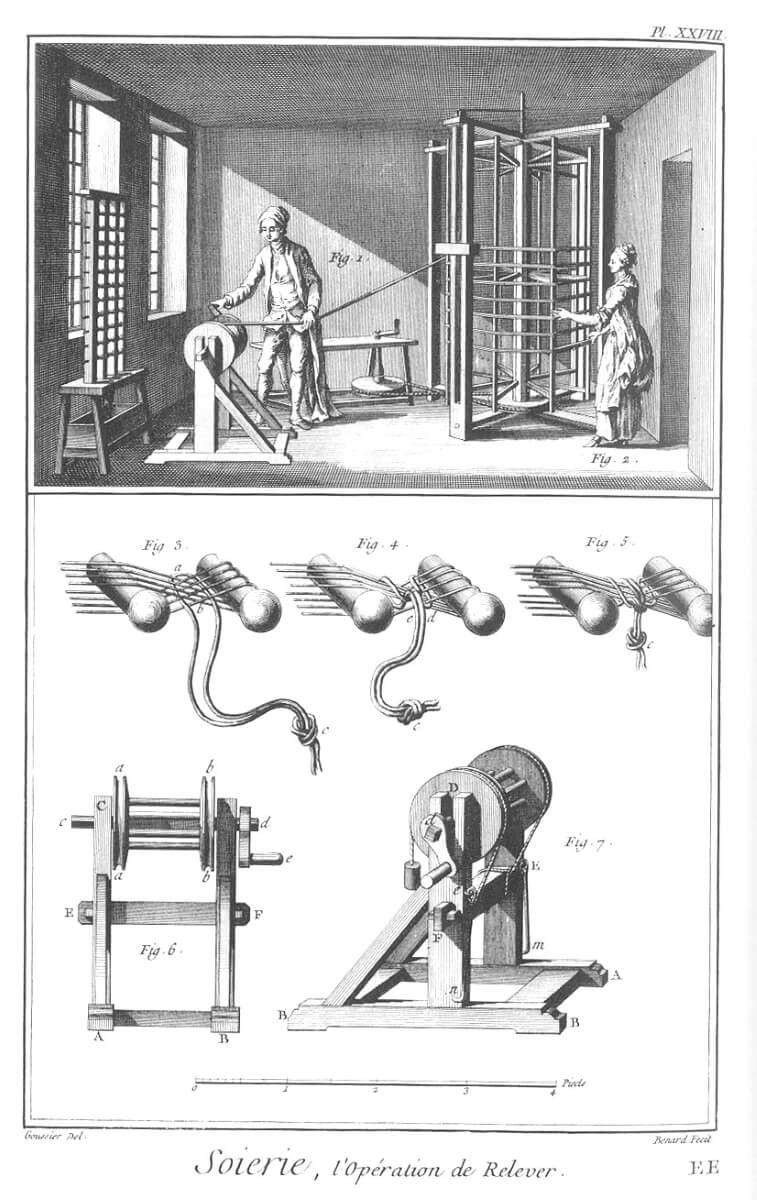

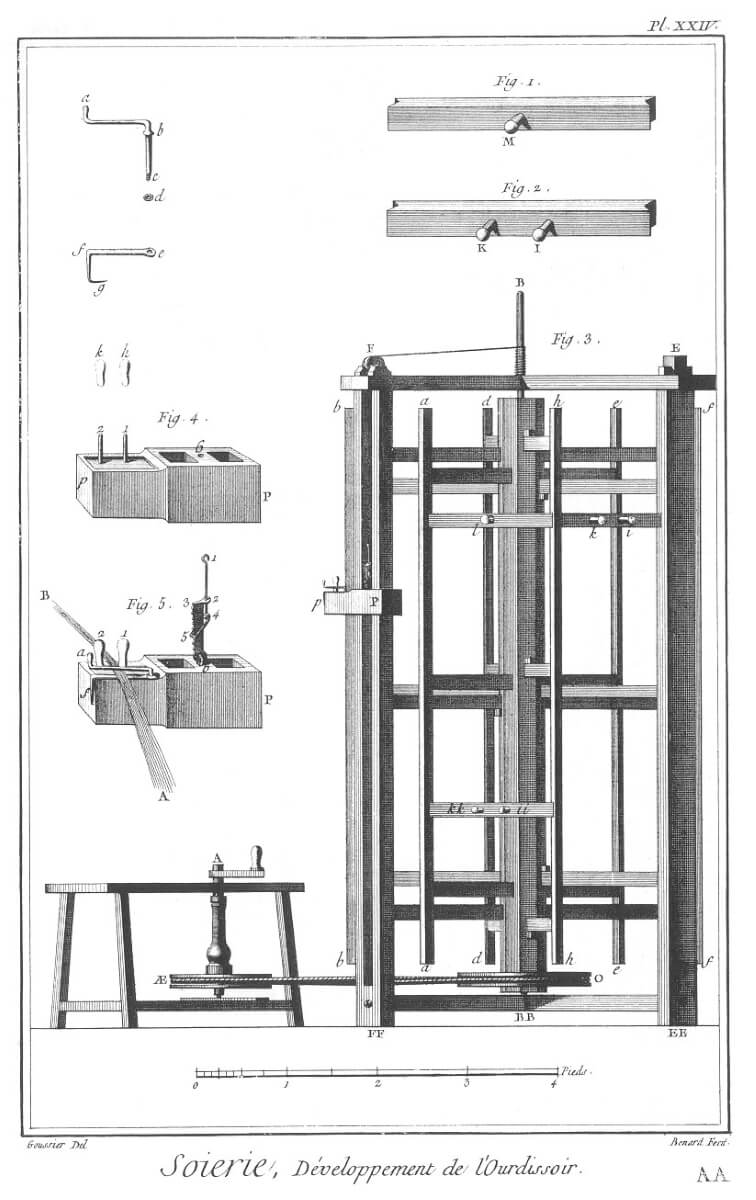

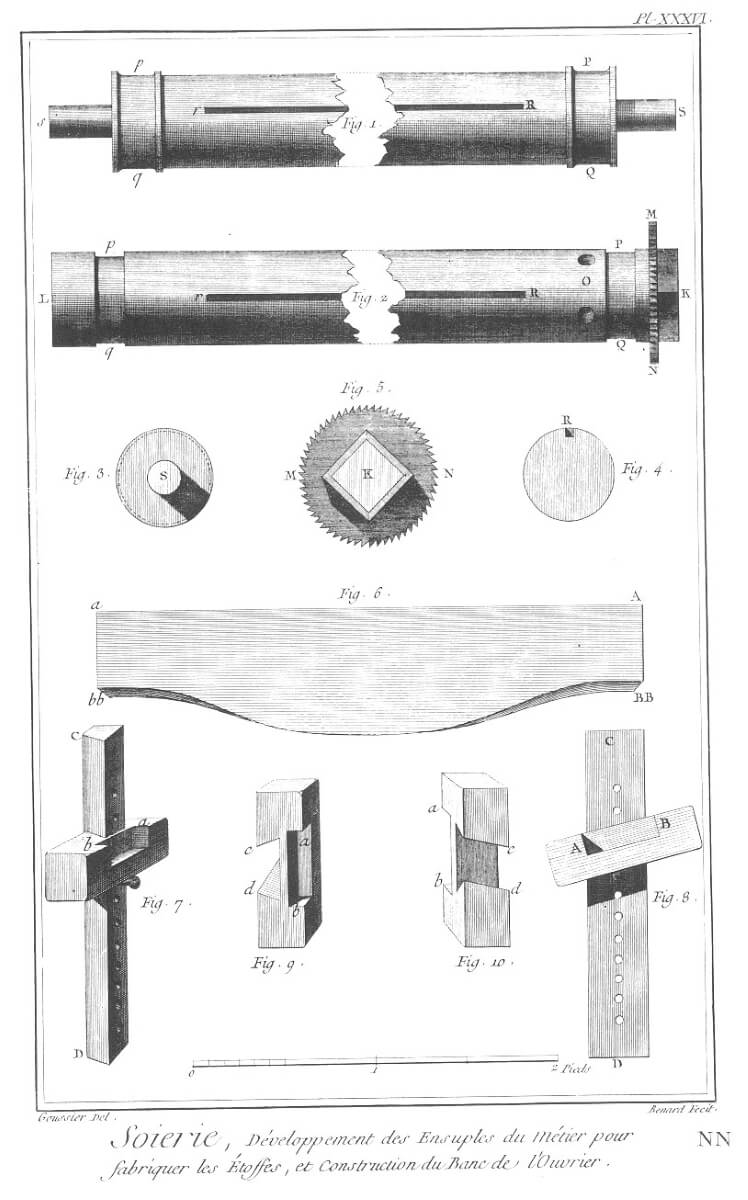

At the end of this operation, the band of threads will be removed by the weaver, forming a braid. After that, the braid will be loosened and rolled up on the horizontal cylinder.

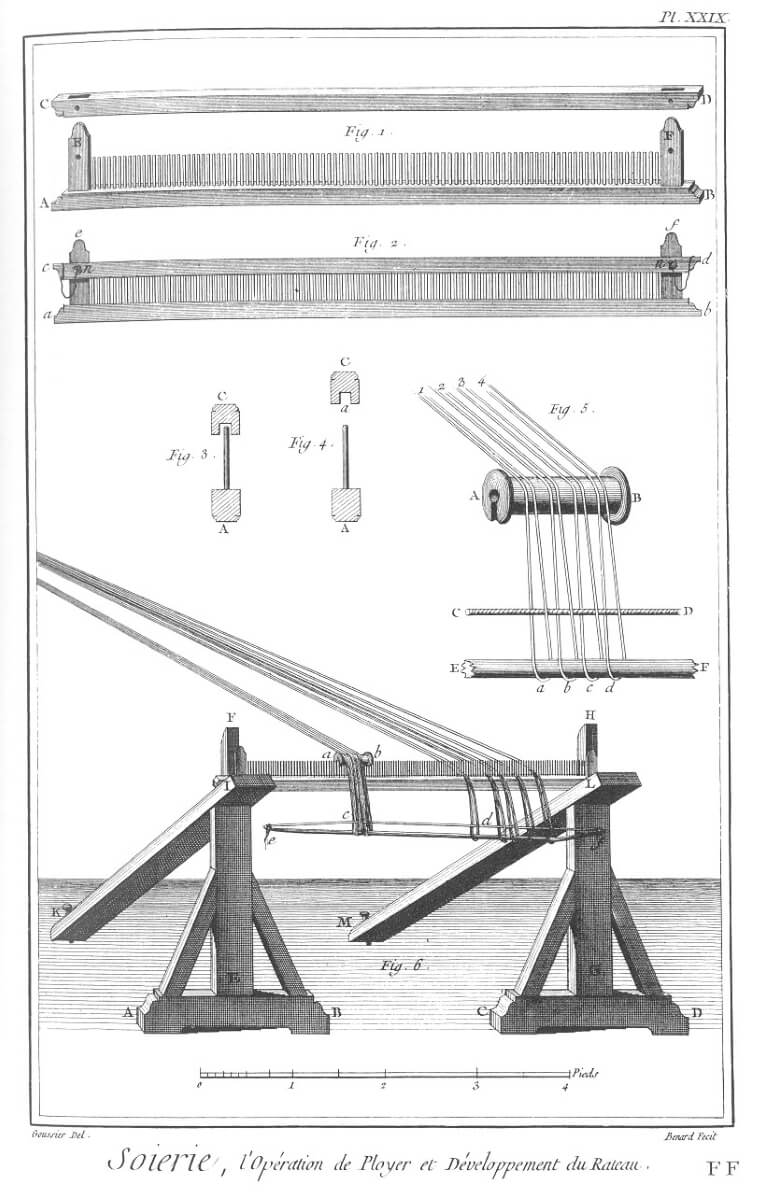

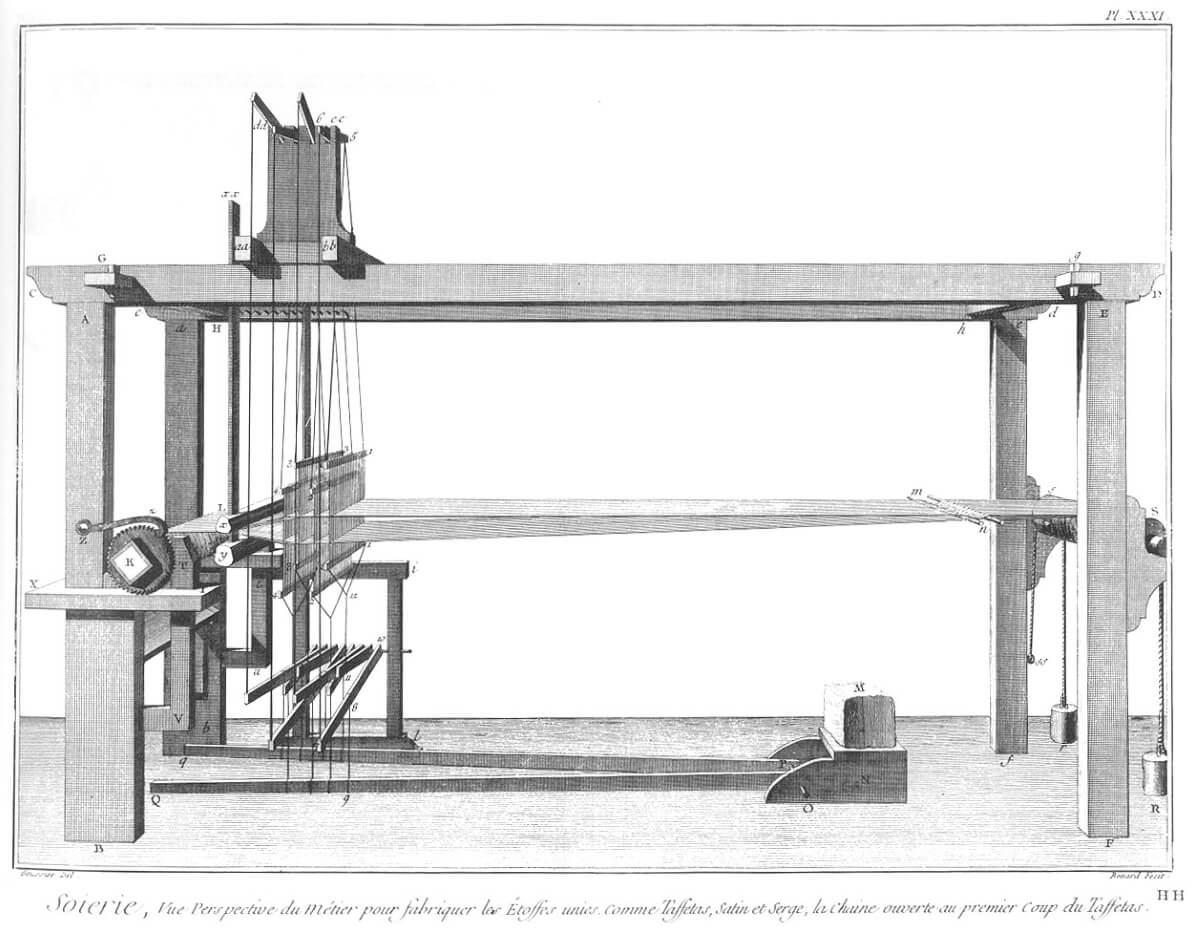

The last stage of the warping process consists in moving the threads from the cylinder to the beam, that will then be placed under the loom.

Our warper is therefore hand-operated and dates back to the 18th century: it is identical to that depicted in the Encyclopedia of Diderot and D’Alembert.

The final stage: preparing the beam

The threads thus collected by the weaver, as you’ve seen in the video, pass through a long “comb” and are rolled around the beam, with the right tension. If they are cotton threads, they simply need to be knotted, in order to complete the preparation of the warp. Silk threads, on the other hand, are glued one by one with gum arabic.

Now all one has to do is load this huge cylinder onto the loom and start weaving a handmade velvet.

The images at the bottom of the page are taken from the Encyclopedia of Diderot and D’Alembert.

The photos of this article taken inside the Tessitura are by Sara Furlanetto.